Rock Bolts

Horizontal toe support for steel sheet piles on bedrock

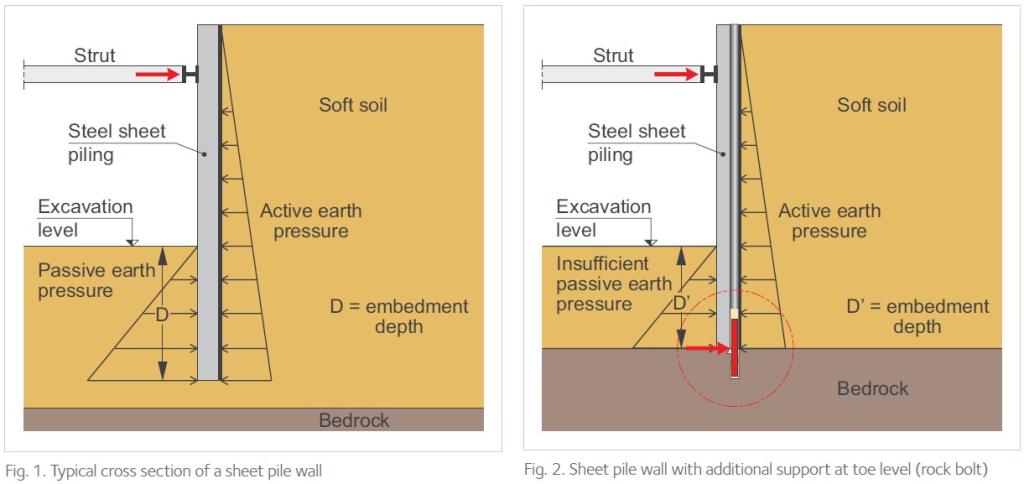

Steel sheet piles retaining walls need to be embedded a minimum depth in the ground in order to generate sufficient passive earth resistance at the bottom of the wall.

However, in Nordic countries the soil consists quite often of soft clay deposits overlying bedrock, and similar ground conditions exist in other countries.

Although it is possible to install sheet piles into the bedrock with installation aids such as drilling or blasting of a small trench in the upper layer of the bedrock, it is easier and faster to apply less destructive installation methods.

For excavations in such soft soils with limited thicknesses of soft soil layers above the bedrock, or where the excavation level lies below the bedrock level, it is common practice in Nordic countries to support the toe of the sheet piles with additional rock bolts (dowels).

Download

English

English