About us

Smart, resilient and sustainable steel sheet piling technology

ArcelorMittal, as a global leading steel producer, committed in 2021 to reduce its CO2-eq. emissions in Europe by 35% by 2030 and aims at reaching carbon neutrality globally by 2050. Our values are Safety, Sustainability, Quality and Leadership.

ArcelorMittal Sheet Piling is the worldwide leader in sustainable steel sheet piling technology, providing the most innovative foundation solutions. Our products are used worldwide for the construction of quay walls, waterways, flood protection barriers, mobility infrastructure projects and containment structures. ArcelorMittal Sheet Piling oversees the sales, marketing and promotion of foundation solutions. Our steel sheet piles are manufactured in Europe.

We offer complete package solutions, based on our wide range of products and services, expert technical support from the early design stages of a project to its completion, customized fabrication, just-in-time delivery and after-sales services. Our innovative solutions and technical support allow the design of optimized, sustainable and efficient steel sheet piling solutions.

ArcelorMittal’s piling series are especially suitable for quickly and reliably building cost-effective structures. They are characterised by excellent section properties, for instance a highly competitive ratio of section modulus to weight, as well as high moments of inertia. Steel sheet piles and foundation products are manufactured according to the European standards, but they can also be supplied according to other international standards (e.g. ASTM).

Decarbonisation is the most important aspect of ArcelorMittal’s long-term strategy. For several years already, the EcoSheetPile™ range has been produced from 100% recycled, recyclable and reusable steel. It is a major contributor to the circular economy. Launched in 2021, the EcoSheetPile™ Plus brand, essential part of ArcelorMittal’s XCarb™ recycled and renewably produced initiative to reach carbon neutrality by 2050, is made from recycled material with additionally 100% renewable electricity.

As project owners start integrating green credentials assessment rules in their tendering processes with fair monetization processes, bids that offer sustainable construction solutions with a reduced carbon footprint have a tangible advantage.

Production Centres

Steel sheet piles and combined walls supplied by ArcelorMittal Sheet Piling are produced in 5 different facilities in Europe:

Hot rolled steel sheets piles

Hot rolled steel sheets piles

Hot rolled steel sheets piles

Cold formed steel sheet piles

Steel tubes

ArcelorMittal’s hot rolled sheet piles are manufactured according to

the European standard

EN 10248

Part 1 and 2

Production facilities in Luxembourg

ArcelorMittal Luxembourg is one of the European top producers of long products such as beams, steel sheet piles and other special sections, which lead the path to the modern construction industry providing innovative steel solutions.

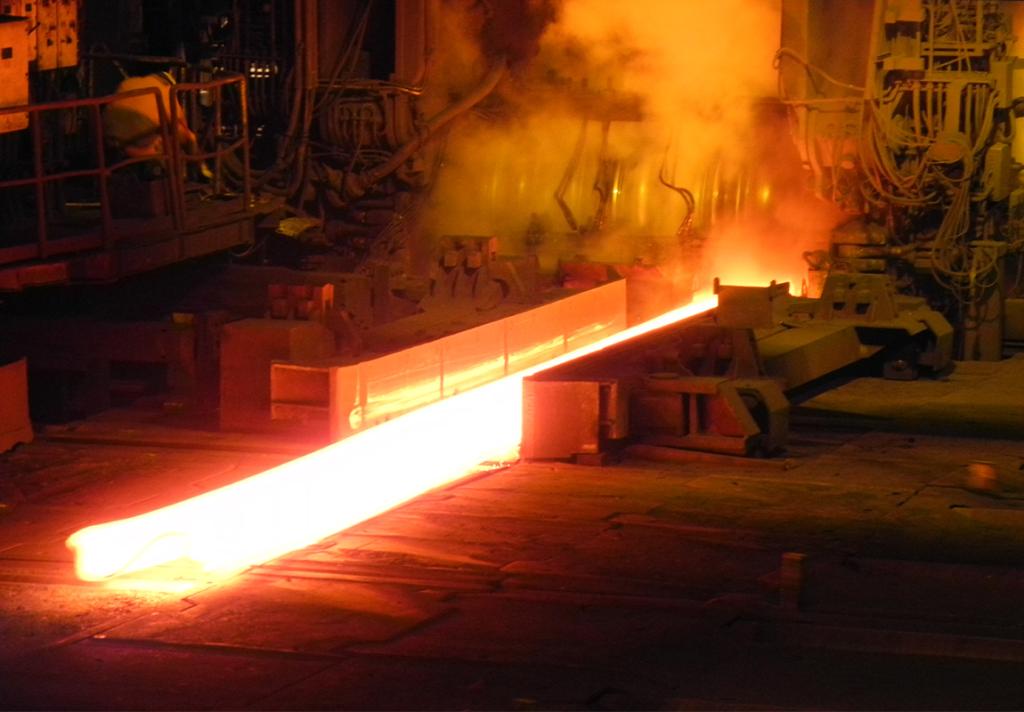

These construction products are produced in two steel plants located in Belval and Differdange. Both facilities produce 100% recycled steel using scrap as its main raw material. The scrap is melted in an Electric Arc Furnace (EAF), cast and shaped into beam-blanks in the steel mill, then stored before being reheated in the rolling mill's furnace, and finally hot rolled to its final shape.

ArcelorMittal Belval & Differdange is certified ISO 9001, ISO 14001, ISO 45001, ISO 50001 and BES 6001.

ArcelorMittal also produces rails, special sections and steel wire products in other facilities in Luxembourg.

Belval mill

The steel plant located in Belval is the world’s largest rolling mill of hot rolled steel sheet piles and has been playing a leading role in the development of piling technology for over 100 years (formerly ARBED).

The Belval site consists of a steel shop with an electric arc furnace and a continuous caster. It has two specialised rolling mills, one dedicated exclusively to steel sheet piles (Mill 2), and one dedicated to standard steel sections (TMB).

The first steel sheet piles that were rolled in 1911 and 1912 were the Ransome and Terre Rouge profiles. Since then, the available range produced in ArcelorMittal’s Mill 2 has undergone a continuous improvement process that allows the production of the revolutionary AZ® sections (Z-type) up to 800 mm (31.5") wide, as well as the current U-type sections with section widths up to 750 mm (29.53").

Note that Mill 2 in Belval is the only rolling mill in the world that has the knowledge and state-of-the-art technique to produce steel sheet piles in the more corrosion resistant AMLoCor® steel grade.

The series of hot rolled steel sheet piles manufactured in Belval are

- Z-type: AZ-800 | AZ-750 | AZ-700 | AZ

- U-type: AU | PU

- straight web type: AS 500

Differdange mill

The Differdange mill is composed of a steel shop with one electric arc furnace and a continuous caster, as well as one rolling mill, known as the Grey Rolling Mill. Differdange produces the HZ-M sheet piles, as well as heavy sections - including the Jumbo sections used in skyscrapers.

The Differdange mill holds several world records, including that for the first beam measuring one meter high (3.28 ft high), the beam with the heaviest metric weight (1 370 kg/m) and the largest beam (1 100 x 400 mm).

The HZ-M® sections are the stiffest sheet piles in the world, the key element to build up the most competitive high section modulus combined wall systems. Their main applications are harbour construction and deep excavations all over the world.

Beams produced in the Grey Rolling Mill have been used for the most prestigious landmarks, including the Freedom Tower in New York (USA) and the World Financial Centre in Shanghai (China).

The series of hot rolled steel sheet piles manufactured in Differdange is

- HZ-type: HZ-M

Production facilities in Poland

The Dąbrowa Górnicza site is a fully integrated plant with a long tradition and features 1 blast furnace, 1 steel shop, 1 continuous casting and 2 long products rolling mills. The heavy section mill is used to roll beams, channels, mining profiles, rails and sheet piles. The medium section mill is a continuous mill producing beams, angles and channels.

The mill is is certified ISO 9001, ISO 14001 and ISO 50001, as well as PN/N 18001.

Besides the rolling mill, the plant is equipped with a service centre for cold cutting, pairing and crimping, as well as equipped with a finishing area for welding, sealing and coating.

The series of hot rolled steel sheet piles manufactured in Dąbrowa Górnicza are

- U-type: GU | GU-N

Production facilities in France

ArcelorMittal manufactures cold formed steel sheet piles in Messempré, a town located in the north-east of France.

The story of the Messempré mill goes back to the beginning of the XIXth century when Forges Boutmy was founded. The family De Wendel acquired the factory in 1912 and started producing thin steel sheets. The industrial development lead to the cold-forming of steel sheet piles as early as 1955.

The Messempré mill is currently the worldwide leader in terms of cold forming steel sheet piles with interlocks complying with the European standard. The company has been certified ISO 9001 since 2004 and its products comply with European standard EN 10249, Parts 1 and 2.

The series of cold formed steel sheet piles manufactured in Messempré are

- Z-type: PAZ

- Omega type: PAL | PAU

- Trench sheets: RC

Production facilities in The Netherlands

The spiral mill is located on its site in Dintelmond (The Netherlands). This mill is especially designed for the production of spirally welded pipes for foundation purposes.

Production is 100% controlled and certified with delivery of 3.1. certificates according EN 10204-2004. Pipes can be produced with diameters up to 3 000 mm and wall thicknesses up to 25 mm. The spiral mill can provide pipes in all requested steel grades due to its worldwide network of coil producers. Pipes can be produced with lengths up to 53 m without circumferential weld. Longer tubes can be achieved by welding.

There is a coating facility present on the production site. Several specialized welding facilities are placed in line with the spiral mill for executing specific works like welding connectors or other steel parts, and making butt welds.

The series of steel tubes for foundations manufactured in Dintelmond are

- spiral weld tubes: diameters 864 – 2997 mm, thicknesses up to 25 mm

Research and development (R&D)

ArcelorMittal Sheet Piling in collaboration with ArcelorMittal Global Research and Development department in Esch-sur-Alzette invests significant resources into steel sheet piling R&D projects, and collaborates with many external partners . The fields covered by R&D are among others

- new piling sections,

- installation of piling (driveability, reduction of nuisances),

- new applications for steel sheet piling,

- enhanced design methods for retaining walls,

- durability (corrosion protection systems, design)

- sealing systems for the interlocks.

More details on the R&D departments and missions can be found in these external links:

ArcelorMittal Europe Releases 2023 Fact Book

Did you know that ArcelorMittal Europe employs over 62,000 individuals from 74 different nationalities, or that our steelmaking facilities span 9 European countries?

From the moment you hit your alarm clock in the morning, flick on your bathroom light, commute to work by car, train, tram, bike, or bus, enjoy a meal at a restaurant, crack open a refreshing canned drink, or even bake a cake - ArcelorMittal Europe's steel is an integral part of your daily life.

That's why we've compiled everything you need to know in our fact book, now enhanced with augmented reality features accessible via QR codes.

Experience our Fact Book in Augmented Reality:

- Watch moving and informative videos.

- Discover how steel facilitates the way you live and contributes to a sustainable future.

- Browse the interactive map for a vast range of end applications made with our steel and used all around the world.

- Find a contact person near you to answer your questions or to get the right steel for your project.

Dive into a world of information with our rich, interactive content!

Please note, the fact book provides a snapshot and not an exhaustive list of information.

For more details, visit europe.arcelormittal.com or check out ArcelorMittal’s Annual Report 2023.

Learn more about foundation solutions with steel pipes

Trademarks ArcelorMittal is the owner of following trademark applications or registered trademarks: "AS 500", "AU", "AZ", "GU", "HZ", "HZ-M", "HZ/AZ", "PU", "AMLoCor", "AKILA", "Beltan", "ROXAN", "Arcoseal", "HISTAR", "XCarb", "EcoSheetPile".

In communications and documents the symbol ™ or ® must follow the trademark on its first or most prominent instance, for example: AZ®, AU™.

Credit lines must be used on all communications and documents where a trademark is used, for example:

AZ is a trademark of ArcelorMittal group

AU, AZ and HZ are trademarks of ArcelorMittal group AZ 25-800 is a steel sheet pile manufactured by ArcelorMittal group