Sustainability

Building a better world with sustainable steel sheet piles

Sustainability

ArcelorMittal is committed to create high quality, sustainable steel for people all over the world. Corporate responsibility and responsible sourcing are part of the company's core values.

We continue investing in our production sites and in R&D to reduce the environmental impact of our products, and to fulfill all quite strict European regulations about emissions to air and soil.

We believe that the choice of a product should be based on sustainable criteria. Such criteria are not straight-forward, but architects and design engineers should add environmental and social criteria in the tender procedures. Public authorities can do it based on a European Directive, which was revised in 2014 (European Directive 2014/24/UE). Some European countries already use environmental and social criteria in their tenders. This is a good way to challenge the manufacturers to reduce their environmental footprint.

Circular economy will definitely lead to saving natural resources, and consequently to preserve our planet. Reuse and recycling can largely contribute to this achieve this noble objective.

However, sustainable criteria must be unbiased, and based on relevant technical facts validated by independent experts. Life Cycle Analysis (LCA) for a specific project, and Environmental Product Declarations (EPD) are some of the tools that can be used to compare different solutions and different products. The crucial question is which is the best method to take into account non-financial criteria? Can monetization, like it is done is some countries, be the solution? Or using weighting factors for each criteria? It is a controversial topic, but it is important to start promoting this new approach to cost-efficiency, taking into account the whole life-cycle of a structure, including dismantling and recycling.

For sure, at this stage, the initial investment required (intial cost) of a structure will most often be the main weighting factor, but why not reward the manufacturers who care about the future of our planet?

In this section, you will find more details about our commitment, and the advantages of using steel sheet piles in the infrastructure and other domains.

EcoSheetPile™ Plus and XCarb®

Sustainable solutions to reduce the environmental impact of your projects

Decarbonisation is the most important aspect of ArcelorMittal’s long-term strategy. We align with the Paris Agreement’s goals and the European Green Deal. We committed in 2021 to reduce European CO2-equivalent emissions by 35 % by 2030 and reach net-zero by 2050. Our new brand, XCarb® is designed to bring together all of ArcelorMittal’s reduced, low and zero-carbon products and steelmaking activities.

The new EcoSheetPile™ Plus brand, an essential part of the XCarb® recycled and renewably produced initiative, is based on the EAF route using 100 % recycled material and in addition using 100 % renewable electricity sourced from the same power grid. This allows the manufacturing of the new EcoSheetPile™ Plus with even less emissions than with the usual energy mix. Certified by a specific Environmental Product Declaration (EPD), the production of the EcoSheetPile" Plus range emits as low as 409 kg CO2e per tonne of finished product. It comes also with a 'Guarantee of Origin' certifying the renewable sources for the electricity, audited by an external third party.

Circular Economy

Steel is a permanent material: never consumed, but continuously transformed; the use of natural resources for producing steel the first time is therefore a transformative process, making iron available in a more “practical form” for subsequent uses (life cycles), and thereby reducing the medium/long term pressure on natural resources.

Circular economy has the objective to reduce the creation of waste systematically throughout the different life cycles of a product. This is in contrast to linear take-make-dispose economy, which wastes large amounts of embedded materials, energy and labour.

ArcelorMittal Sheet Piling is a major actor in the circular economy, aiming for better productivity and reduction of waste. Steel sheet piles can be reused several times in temporary applications, thus reducing the environmental impact each time the sheets are re-used. At the end of life, when they cannot be reused, 100% of the steel can be recycled.

Reduce

Today's steel industry prioritizes lighter, stronger materials. For example, modern steel sheet piles like the AZ 14-770 are 26% lighter than their 1950s counterparts, offering significant weight savings. Higher-grade steel options with up to 500 MPa yield strength provide added strength with minimal cost difference. European design codes now include plastic section modulus, boosting resistance by 10% to 25%. Innovation in steel technology has halved the steel needed for retaining walls over the years, offering sustainable and cost-effective solutions.

Reuse

Steel sheet piles offer eco-conscious, reusable solutions for temporary needs, minimizing environmental footprint. When no longer needed, 100% of the steel can be recycled. Innovative business models like short-term rentals and buy-back options promote sustainable practices, benefiting both contractors and the environment.

Recycle

Steel's perpetual nature allows for continuous transformation, never truly consumed but endlessly repurposed. As a material with inherent value, steel sheet piles can be extracted post-service and recycled at 100%. Unlike other materials, steel retains its quality through recycling, contributing to sustainable construction practices and minimizing environmental impact.

Responsible Sources

Responsible Steel™

ArcelorMittal Belval, Differdange, and Dabrowa obtained the ResponsibleSteel™ certification on July 20th, 2021, a major recognition after several months of audits. The Luxembourg sites, including Rodange, with the ArcelorMittal sites in Belgium (Geel, Genk, Ghent and Liège) and Germany (Bremen and Eisenhüttenstadt) are the first in the world to have been certified as meeting the requirements of ResponsibleSteel, the steel industry's first multi-stakeholder standardization and certification initiative globally.

Besides quality and Health and Safety criteria, the ResponsibleSteel certification encompasses stringent criteria covering a wide range of social, environmental and governance criteria, including:

- climate change and greenhouse gas emissions,

- the conservation of water resources and biodiversity,

- human and workers’ rights,

- relations with stakeholders and business integrity.

Responsible Sources

Responsible Steel™ & BES 6001 (UK)

EPD & LCA

Environmental Product Declaration (EPD)

An Environmental Product Declaration (EPD) is a verified and registered document that communicates transparent and comparable information about the life cycle environmental impact of products. It is created by the manufacturer, peer reviewed by independent bodies on the basis of ISO 14025 and EN 15804 standards, and published by an environmental labelling organisation. Thus, EPDs are suitable as proof of environmental requirements in public procurement processes.

In order to develop this document, ArcelorMittal Sheet Piling analysed the full production process and performed a Life Cycle Assessment (LCA) of its steel sheet piles.

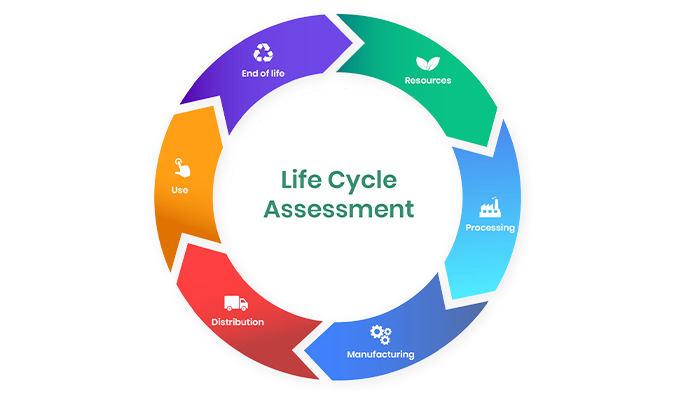

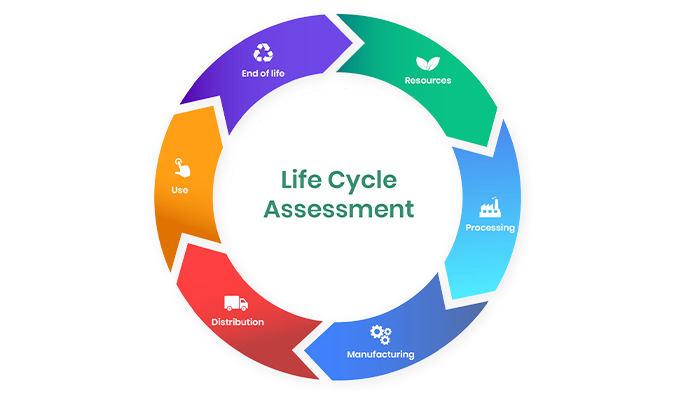

Life Cycle Assessment (LCA)

An LCA is a technique for assessing the environmental aspects and potential impacts associated with a product or service over its life cycle. Based on our EPDs, we elaborated an LCA for two cases studies comparing the environmental impact of different solutions for the execution of the retaining walls of

- a quay wall of a cruise ships terminal

- an underground car park

The LCAs were drafted by environmental experts from our R&D department, based on a design of the structure performed by an independent consulting engineering firm. In order to publish a comparative LCA, but also to be transparent, the LCAs were peer-reviewed by independent experts.

Feel free to contact us for a basic calculation of the LCA for your specific project. It is free, simple and very instructive.

Looking for answers ?

Check for the most frequently asked questions regarding sustainability