Hazard Protection Solutions

Faster construction of flood protection barriers with steel sheet piles

Keeping us safe with steel sheet piling solutions. Steel sheet piles help safeguard our communities from natural disasters.

Dykes and flood protection barriers made of steel sheet piles are one of the most efficient ways to protect against flooding and rising sea levels. Requiring little equipment, they can be easily installed even in remote locations with certified quality anywhere in the world. Dixeran® on-site declutching detectors ensure the integrity of the installation.

Flood Protection

Sheet pile walls can be used in a variety of ways for flood defence systems.

Possible applications include:

- When used as new protection structures, sheet piles can ensure: - Watertightness - Protection from dryness (weep holes) - Support - Earth stabilization;

- For existing embankments: sheet piles ensure increased strength

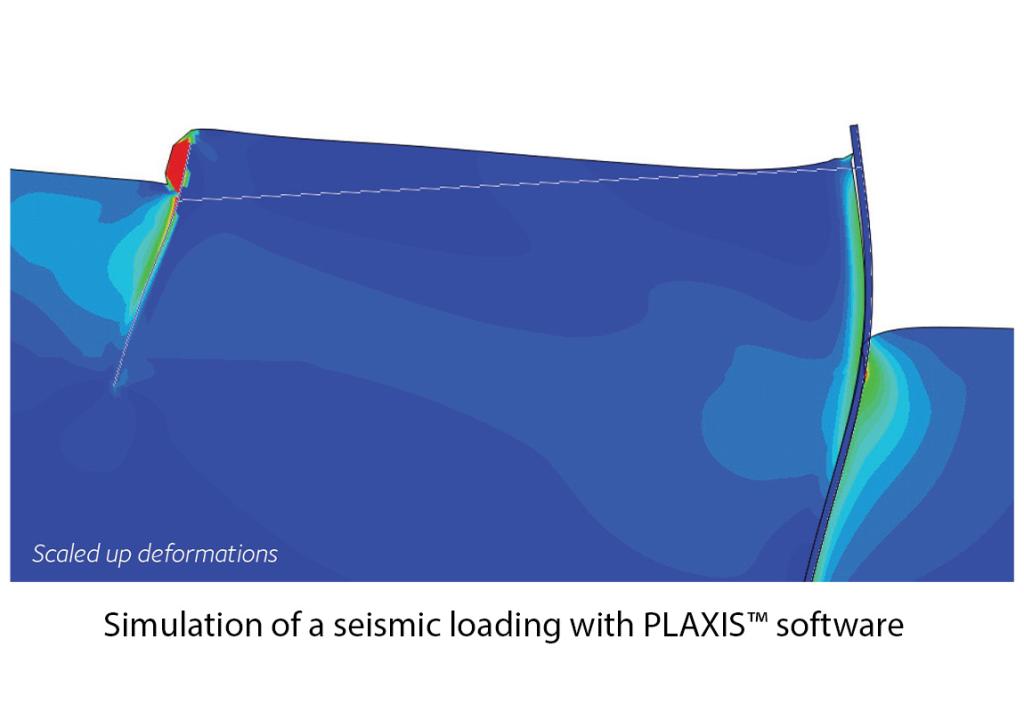

- Adequate to be used in high seismic areas due to the intrinsic properties of steel (ductility and flexibility, lighter structures lower inertia)

- When space is an issue (i.e. ports or urban areas): can form cantilever floodwalls.

- Are cost-effective: high speed of installation, immediate start, short preparation period

- Adequate to work in urban areas: vibratory sheet pile drivers less disturbance during installation (silent press equipment)

With a sheet pile wall, not only can an embankment be made watertight, but it can also be modified to hold back a larger design flood without requiring greater footprint. This is a simple matter of designing the sheet pile wall to project the requisite height above the crest.

When space is an issue, e.g. in ports or urban areas, sheet pile walls can form freestanding floodwalls (small footprint) to replace a flood embankment (large footprint).

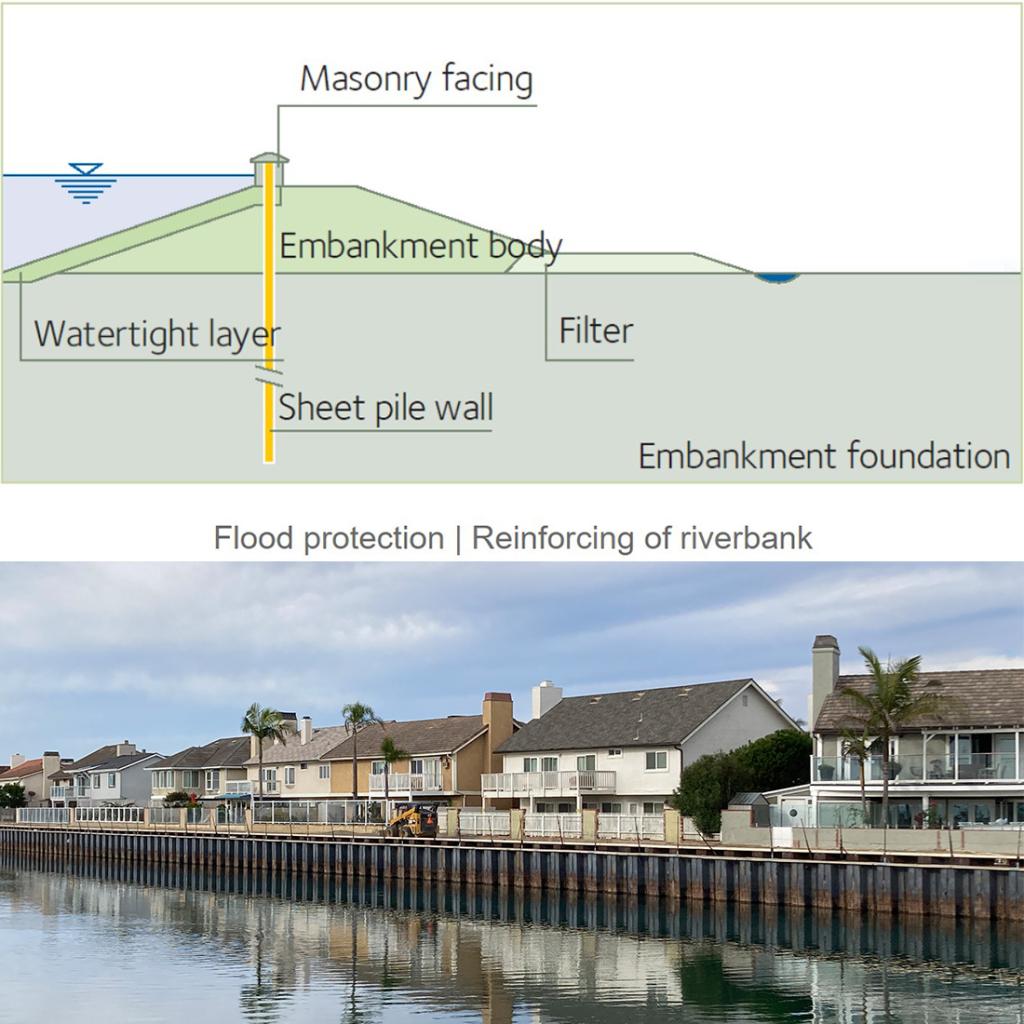

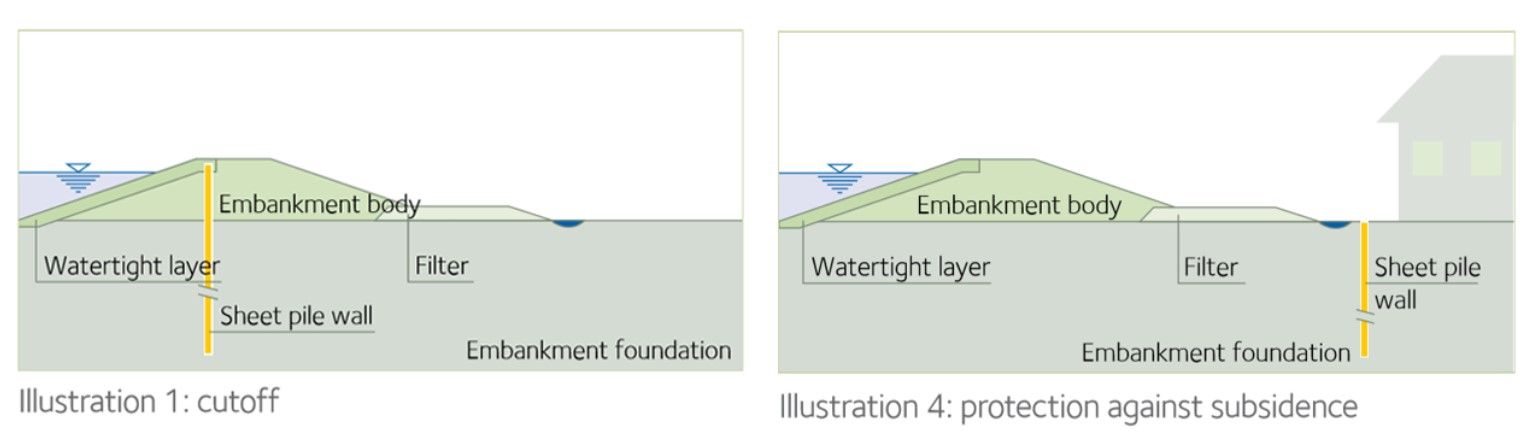

Riverbank protection & dykes

Steel sheet pile walls can be used in a variety of ways for riverbank protection and dykes. For new embankments they can ensure watertightness, support, and stabilization. They are also used to strengthen existing embankments and can serve as a cut-off wall.

The required watertightness of sheet pile cut-offs is often obtained through natural deposition of soil in the interlocks, or with an additional sealing system.

For the stability, sheet pile walls can be designed to mechanically reinforce the bank. Their flexibility can be very useful: they follow the potential displacement of the soil while keeping their full resistance.

Lastly, sheet pile walls can also protect buildings from subsidence. In this case the sheet pile wall is driven outside the embankment, usually along the toe of the embankment.