EPD & LCA

Environmental Product Declaration & Life Cycle Assessment

Our Environmental Product Declaration (EPD) provides transparent and comparable information about the life cycle environmental impact of our products. Our EPDs cover stringent criteria, such as climate change, water resources, biodiversity, human and workers' rights, and business integrity. We also offer Life Cycle Assessment (LCA) services for two case studies comparing the environmental impact of different solutions for the execution of retaining walls.

Please contact us for a free basic calculation of the LCA for your specific project.

Environmental Product Declaration

An Environmental Product Declaration (EPD) is a verified and registered document that communicates transparent and comparable information about the life cycle environmental impact of products. It is created by the manufacturer, peer reviewed by independent bodies on the basis of ISO 14025 and EN 15804 standards, and published by an environmental labelling organisation. Thus, EPDs are suitable as proof of environmental requirements in public procurement processes.

In order to develop this document, ArcelorMittal Sheet Piling analysed the full production process and performed a Life Cycle Assessment (LCA) of its steel sheet piles.

ArcelorMittal produces hot rolled steel sheet piles in its European plants of Belval and Differdange in Luxembourg, as well as Dabrowa in Poland, and was the first steelmaker to publish in 2016 an EPD dedicated to steel sheet piles.

In the meantime, new European standards were released (EN 15804), and now our sheet piles are covered by EPDs registered by several program operators such as EPD International in Sweden or the German institute Institut Bauen und Umwelt e.V. (IBU), in accordance with ISO and European standards.

The first EPDs that have been published according to EN 15804+A1, are

- 'EcoSheetPile™ Plus', 2021, covering the steel sheet piles manufactured in the two mills located in Luxembourg, which recycle steel in an EAF (Electric Arc Furnace), and produced with 100% renewable electricity, updated in 2023 with EPD International,

- 'Cold formed steel sheet piles', 2019, covering the full range of cold formed steel sheet piles manufactured in Messempré (France),

- 'EcoSheetPile™', 2018, covering the two mills located in Luxembourg, which recycle steel in an EAF (Electric Arc Furnace), updated in 2023 with EPD International,

- 'Hot rolled steel sheet piles', 2016, covering the three mills. This EPD will be replaced with an EPD for the mill in Dabrowa.

Following EPDs for specific countries have also been published recently

- 'EcoSheetPile™ Plus', 2023, MRPI (Dutch programme operator), for the Dutch market, EN 15804+A2,

- 'EcoSheetPile™', 2023, MRPI (Dutch programme operator), for the Dutch market, EN 15804+A2,

- 'EcoSheetPile™ Plus', 2023, INIES (French programme operator), for the French market, EN 15804+A2.

- 'EcoSheetPile™ Plus', 2023, B-EPD (Belgian programme operator), for the Belgian market, EN 15804+A2.

Transport, installation, maintenance, dismantling and other modules are not considered in most EPDs, because this data should be determined for each specific project (in general, their contribution to the environmental impact is quite small compared to the contribution of the production processes), but in some countries, such as France and Belgium, some modules (A4 for transport and A5 for installation) have also to be declared.

Note: an EPD gives a good overall view of the environmental impact of the (annual) production of a product based on its numerous types of applications, but the environmental impact of a product for a specific project should be determined based on a project specific Life Cycle Assessment, in which some assumptions may have to be adapted, for instance about the end of life phases such as the reuse and recycling rates.

Life Cycle Assessment (LCA)

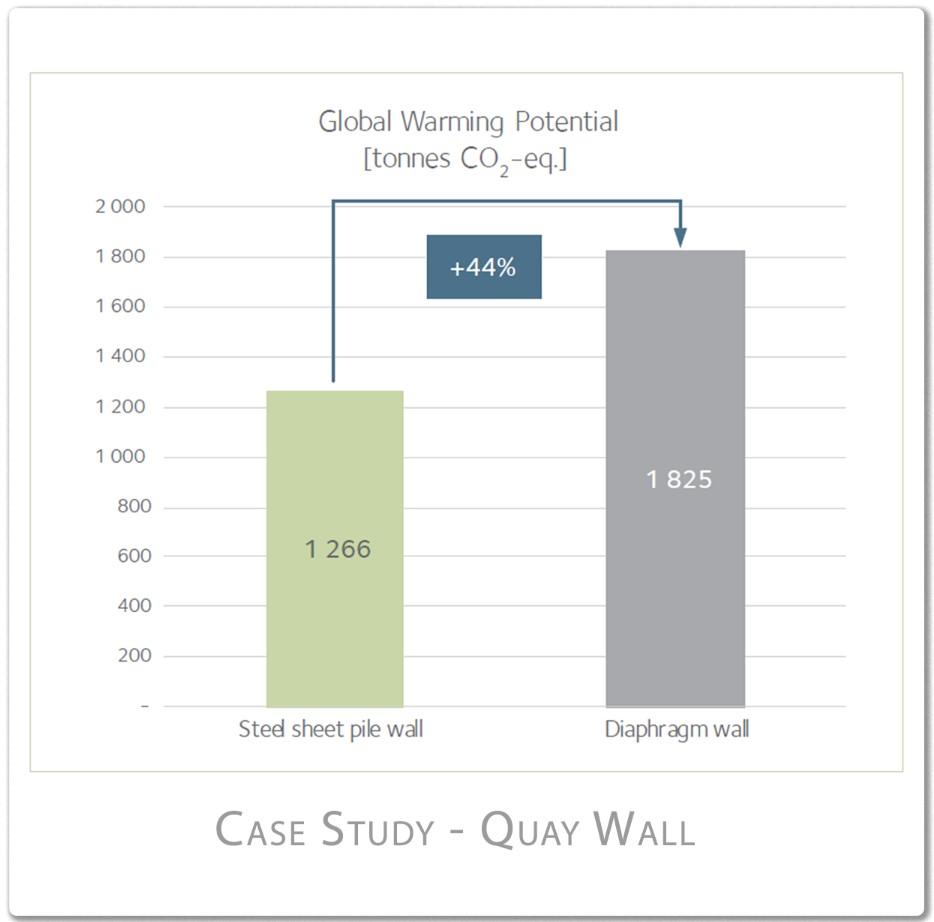

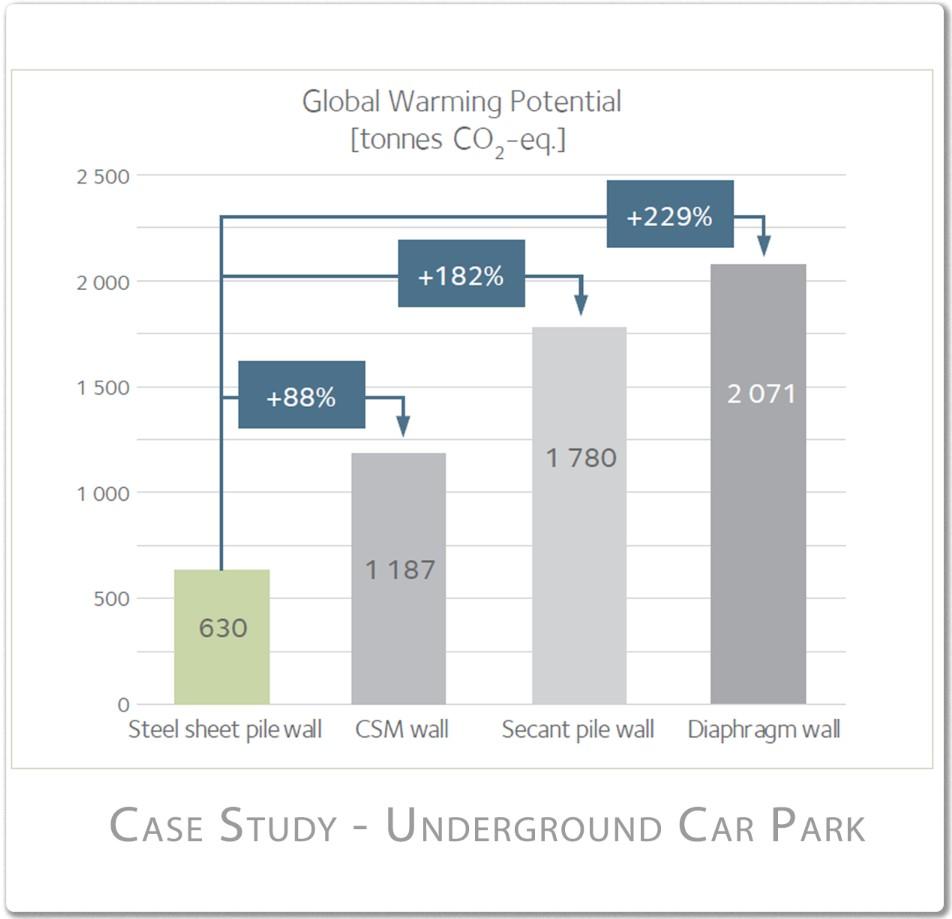

An LCA is a technique for assessing the environmental aspects and potential impacts associated with a product or service over its life cycle. Based on our EPDs, we elaborated an LCA for two cases studies comparing the environmental impact of different solutions for the execution of the retaining walls o

- a quay wall of a cruise ships terminal

- an underground car park

The LCAs were drafted by environmental experts from our R&D department, based on a design of the structure performed by an independent consulting engineering firm. In order to publish a comparative LCA, but also to be transparent, the LCAs were peer-reviewed by independent experts. Please note that there are some intrinsic limitations to any LCA comparison, mainly due to the assumptions that have to be made and due to specific or local parameters that can influence the results of case studies.

Several LCA scenarios were analysed for each case study, and the results show that the steel solution has a significant lower carbon footprint than the alternatives. The analysis considered additional environmental indicators, and the conclusion is the same except for two indicators. The LCA considered the complete life cycle of the structure, including dismantling and recycling of the materials whenever applicable. The analysis focused on the Global Warming Potential (GWP): in the basic scenario, the difference for the quay wall is 44%, and for the underground car park, it is at least 88% (see graph below). You can find more details in the brochures (see links below).

Feel free to contact us for a basic calculation of the LCA for your specific project. It is free, simple and very instructive.

Downloads

FDES (EPD France) - EcoSheetPile™ Plus | 2023

First individual French Environmental Product Declaration (EPD)