SmartSheetPile

Smart steel solutions for innovative infrastructures

In the era of digital transformation, ArcelorMittal is committed to innovating and delivering increasingly efficient, safe and sustainable steel solutions to its customers. Rapid changes in society and markets are driving this transformation. Infrastructure owners and designers are actively seeking smarter solutions to enhance productivity and to reduce risks and maintenance costs.

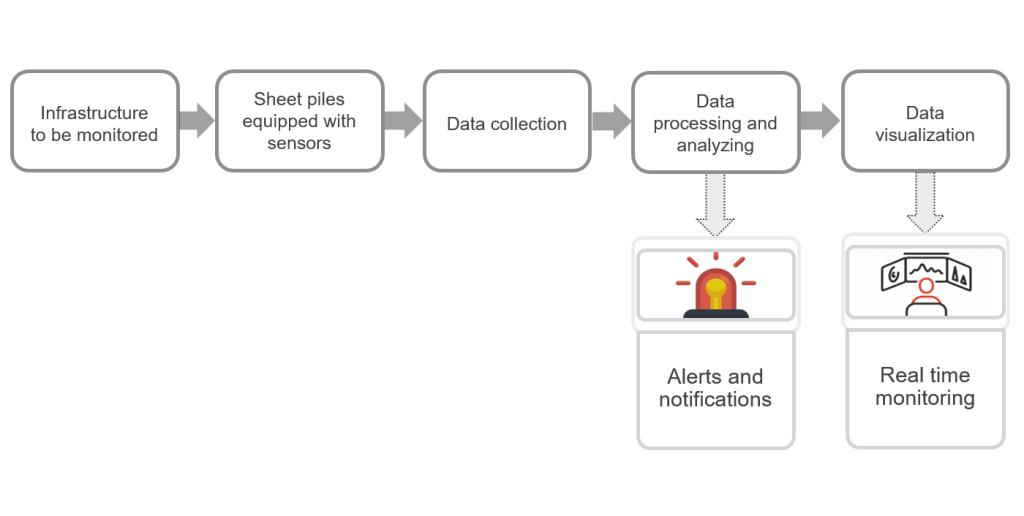

Recognizing the challenges of the future, ArcelorMittal Sheet Piling introduces SmartSheetPile, an innovative health monitoring solution designed to make infrastructures safer, digitally self-aware and integrated with their surroundings. These technologies allow to develop digital twins of the infrastructures by seamlessly integrating physical assets with digital tools.

What is SmartSheetPile ?

SmartSheetPile aims to provide infrastructure owners and operators with a digital asset that goes beyond traditional steel sheet piles by integrating sensors for real-time data collection. It enables the continuous monitoring of the structure's health and general conditions.

Typical use cases are the detection of shocks on the sheet pile walls and identification of their origin, remote corrosion monitoring, alert systems to monitor flood levels and the integrity of flood protection barriers, strain and deformation measurement to assess the infrastructure health and remaining capacity…

Benefits

Secure your assets

The data transmitted by the SmartSheetPile solution helps prevent irreparable damage to the infrastructures. It detects accidental and weather-induced damage. Real-time monitoring of the infrastructure provides early warning of potential catastrophic structural failure, allowing for preventive action to be taken.

Minimize downtime

Whether it is a quay wall, a bridge abutment or a dyke, an unscheduled shutdown can be very disruptive and expensive. It leads to reduced revenue, costly repair work and inconvenience to users. The SmartSheetPile solution provides all the data needed to plan the required maintenance work well in advance, minimizing downtime.

Achieve preventive maintenance

The availability of accurate data on the structural condition of an infrastructure helps optimise its maintenance. Asset owners know exactly when and where maintenance is needed, eliminating the need for costly inspections and unscheduled repair works.

Reveal hidden capacities

The collected data provides accurate information on the state of the structure, the forces involved and their impact on the sheet pile walls, allowing for the discovery of any hidden unused capacity. The usage of the structure can be optimised to benefit from its full potential.

Take on the digital transformation

Digitalisation is a key driver of innovation in design and operation. Live data collected by the SmartSheetPile solution can be integrated into the digital twin of the infrastructure, providing a multidimensional overview of the structure’s design, performance and interactions with the world. It is a single model that brings together all the information needed for effective asset management.

SmartSheetPile

Smart steel solutions for innovative infrastructures

Application domains

Water transport

SmartSheetPile can uncover hidden quay wall capacities and improve productivity. It can be also used to monitor corrosion in real time with precise remaining thickness measurement. It's an essential tool to ensure the sustainability of your quay wall.

Hazard protection

SmartSheetPile can raise the alarm while a catastrophe is coming, it measures the water level and water pressure in real time, detect early signs of potential catastrophic failure.

Mobility infrastructures

SmartSheetPile can monitor the health, loads and deformation of bridge abutments in real time, in addition it can reduce downtime and traffic disruption with more efficient preventive maintenance than a traditional sheet pile

Environmental protection

SmartSheetPile guarantees the integrity of the sheet pile wall against disengagement, as well as the watertightness of the sheet pile wall. An ideal solution for environmental projects, SSP will alert you in the event of a serious malfunction that could endanger the environment on a decontamination site.

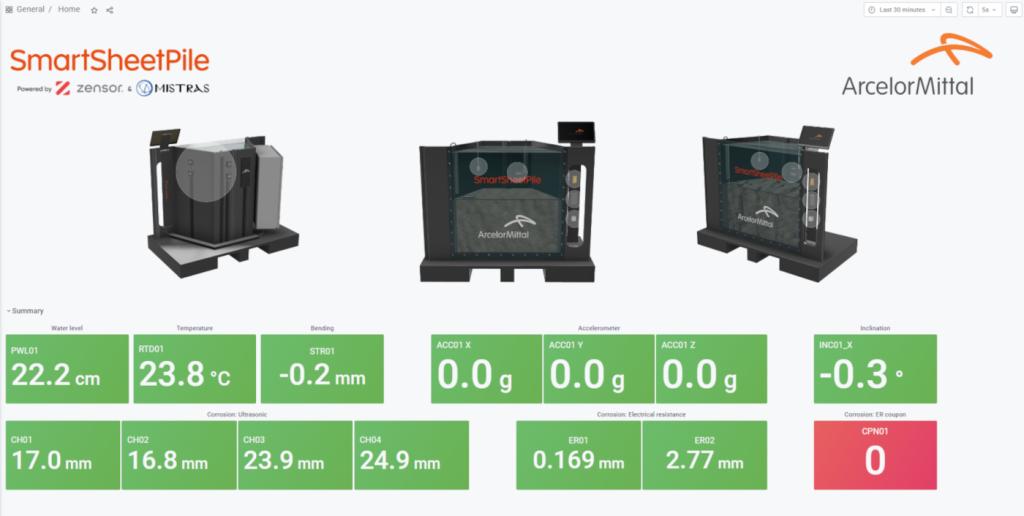

What does SmartSheetPile measure ?

Shocks

Detect shocks and collisions to identify point loads that have a negative impact on the remaining service life. Real-time impact tracking enables the identification of the responsible party for damages and helps claiming for compensation.

Corrosion

Corrosion is one of the most important aspects to monitor for a steel sheet pile, as it is directly related to the remaining service life of the structure. Corrosion sensors provide real-time information on the loss of thickness over time. Several sensor types are available: ER (Electrical Resistance) probes, ultrasonic sensors and corrosion coupons.

Wall integrity

Monitor the integrity of retaining walls by ensuring that the sheet piles are properly interlocked during the installation process.

Deformation

Track the tilting of the sheet pile wall and receive alerts from any sudden significant deformation, which may indicate anchoring failure, wall damage, ground movement, etc.

Strain

Continuous monitoring of strain values on a specific section of the sheet pile wall can be used to track the actual forces affecting the structure: ground pressure, surcharges, tidal activity, etc. Combined with corrosion measurements, strain monitoring allows for a continuous reassessment of the remaining service life.

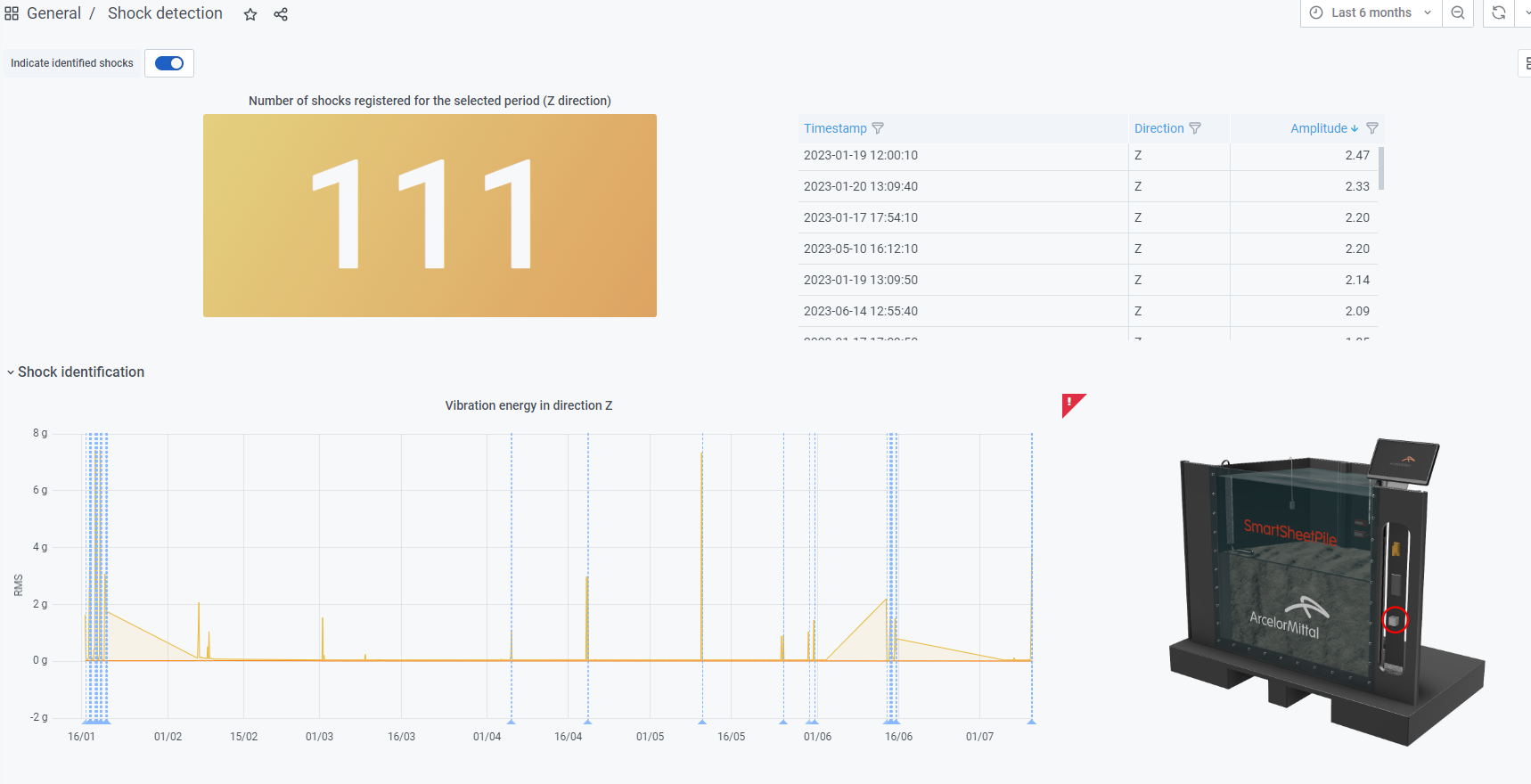

The monitoring system

SmartSheetPile is designed to maintain a continuous monitoring, instantly transmitting the structure's real-time condition data to the cloud. In case of unexpected events such as anchor failure, wall impact, or earthquakes, SmartSheetPile can promptly issue alerts. The solution ensures continuous collection and transmission of high-quality and precise data, enabling informed decision-making. This not only leads to reduced maintenance costs but also optimizes the utilization of structures and extends its lifetime.

Furthermore, the integration of Artificial Intelligence (AI) takes asset management to the next level by enabling predictive maintenance. The vast amount of data collected from sensors is processed and analyzed using advanced AI algorithms. These algorithms identify correlations among monitored characteristics and parameters, enabling the prediction of critical issues and optimizing maintenance plans to prevent potential problems. This proactive approach ensures enhanced efficiency and reliability in asset management.

Online Monitoring Dashboard: the Digital Twin model of the structure allows users to access sensor-specific data, including historical records with dates and corresponding values. In the Figure above, the shock detection sensor recorded 111 shocks during the last six months. The accompanying table showcases precise details, including dates, times, directions, and amplitudes of each detected shock.