Implementation of environmental criteria in civil engineering (infrastructure)

Applying Environmental Criteria in Civil Engineering

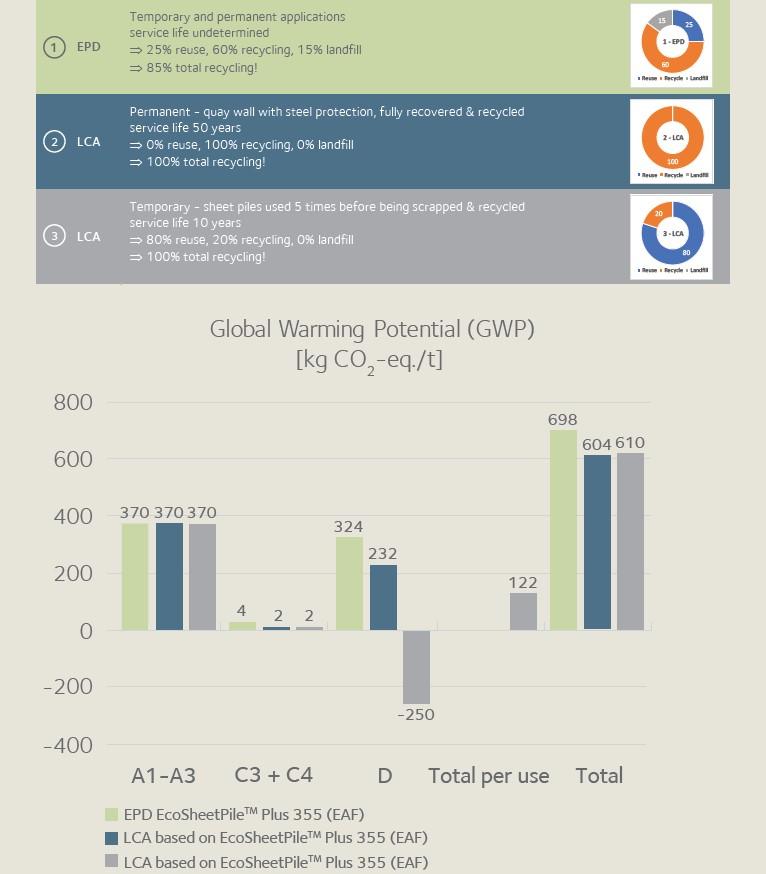

Steel sheet piles are mainly used for permanent applications in civil engineering, predominantly for infrastructure and foundations, i.e. construction of quay walls, retaining walls, underground car parks, bridge abutments,… Besides, sheet piles are used for temporary applications, such as watertight cofferdams in the water, deep excavation in urban areas, etc. One of the key advantages from a financial and environmental point of view is that they can be driven into the ground and easily recovered after their service life, and either reused several times before being recycled or directly recycled.

English

English

German

German

French

French