New BVK headquarters in Munich, DE | 2023

Creating sustainable foundations for the BVK Munich's new headquarters at RS76

On the former Siemens site at Richard-Strauss-Strasse 76 (RS76) in Munich, the new headquarters of the Bavarian Pension Fund (BVK) is being built. ZÜBLIN Spezialtiefbau has been commissioned to create the excavation pit, which is impressive in size and depth.

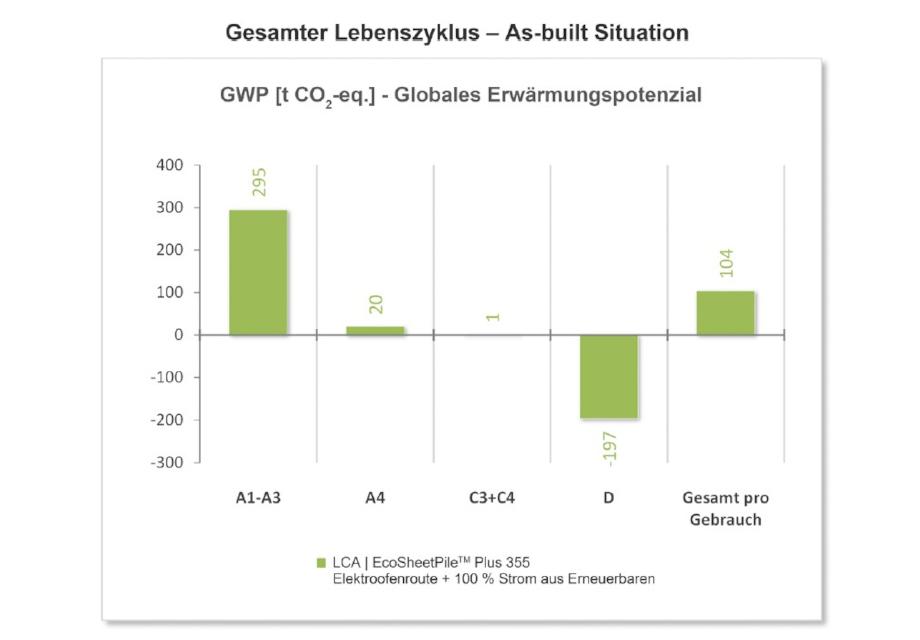

A total of 188,300 m3 of soil will be excavated and disposed of. A temporary sheet pile wall was constructed on the south and east sides of the construction site. The contractor chose ArcelorMittal's PU profiles for the sheet pile wall, which have a very low CO2 footprint due to scrap-based production and the use of renewable energy during manufacturing. The overall project aims for a high level of sustainability and has already been awarded the "Sustainable Construction Site" certificate by the German Sustainable Building Council (DGNB).

English

English

German

German

French

French