Sustainable ports

Life Cycle Assessment

Building a Sustainable Port: Environmental Impact Analysis

Before building a new structure, checking the possibility of extending the service life of existing structures makes sense. This is the best option from an environmental point of view, but most often, old structures need retrofitting. Hence, only an economic and environmental analysis can help the owner to make an informed decision. But when it comes to increasing the dredge level to welcome vessels with higher drafts, or when existing structures are close to failure, building a new quay wall may be the sole viable alternative.

The question is how to build a sustainable port?

ArcelorMittal appointed Tractebel, an independent Belgian consulting engineering firm, to analyse this quite multifaceted topic. The engineers proposed to focus on three key indicators: technical, financial and environmental criteria. Their task consisted in comparing three different technical solutions for above indicators. The selected structure is a cruise ship terminal capable of accommodating the largest cruise ships. It would be built in a Belgian port, with a draught of 13 m in typical soil and load conditions for a Belgian port.

The Life Cycle Analysis (LCA) is based on the bill of quantities prepared by Tractebel and was performed by ArcelorMittal’s R&D department. It has been peer-reviewed by a panel of experts. The objective was to compare the Total Life Cycle Cost, including the burdens or benefits of the end of life phase, which are dismantling and recycling of the building elements, but no reuse was considered.

Download the document

For this type of application, an LCA is a reasonably fair and transparent method to compare different solutions and suppliers. Although not required by ISO and EN standards, an LCA is more accurate and realistic when it uses specific Environmental Product Declaration (EPD) from the producers rather than generic data from databases.

The choice of a solution shall consider several key indicators, the principal one being the construction cost (including the design).

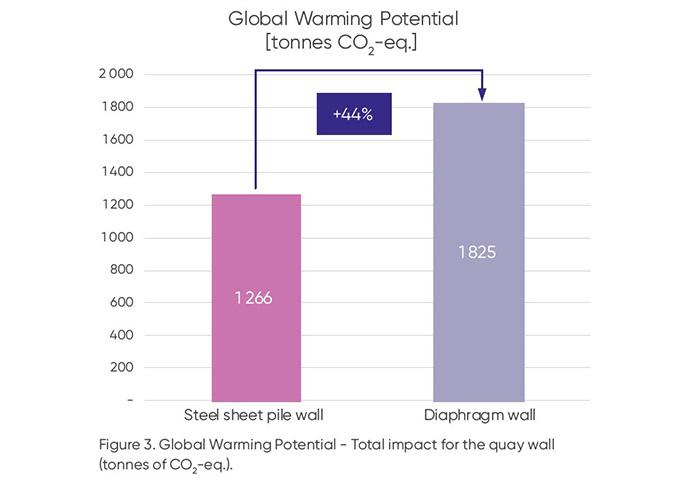

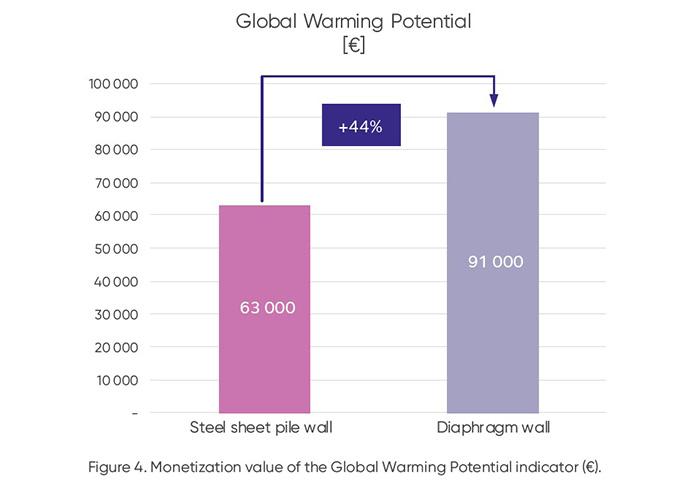

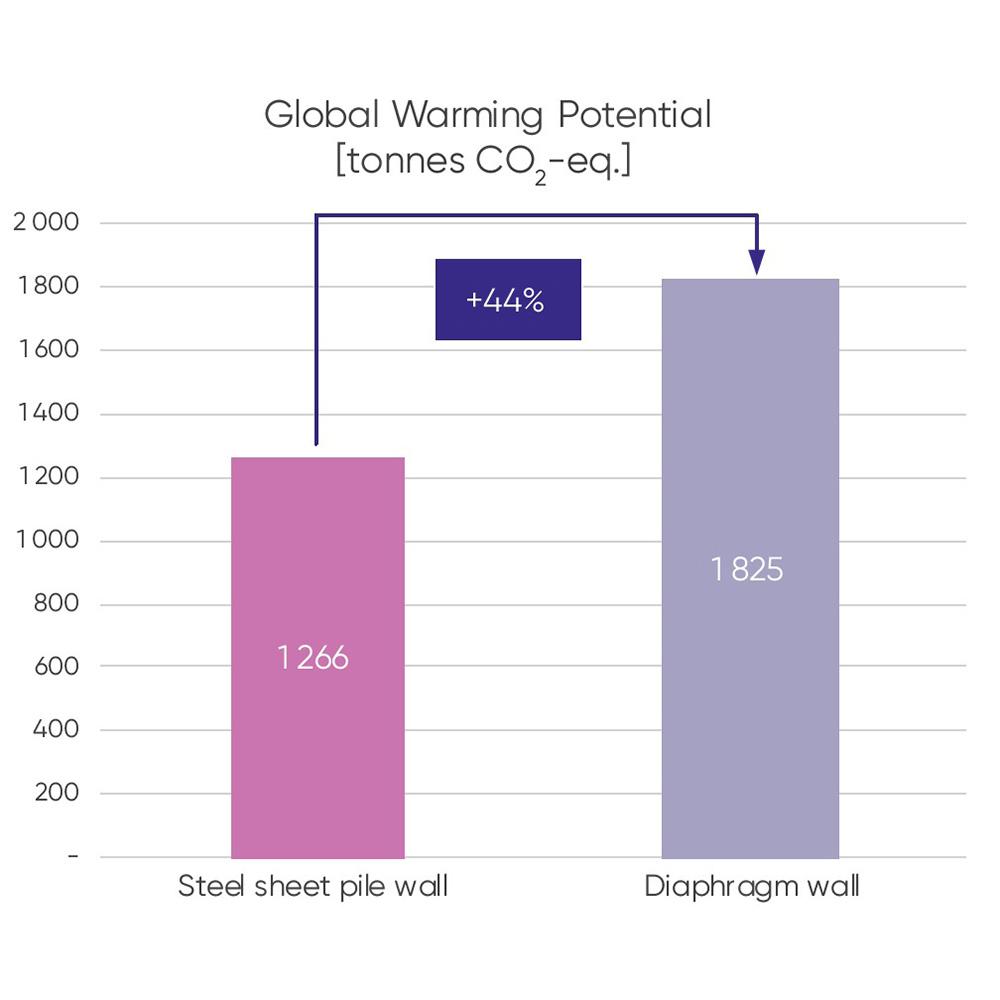

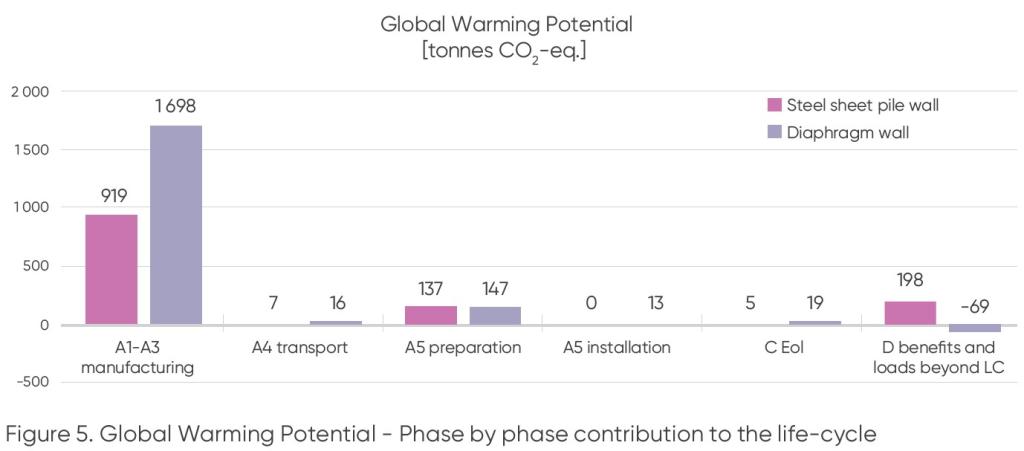

The key environmental indicator analysed in this case is the carbon footprint; its impact for the base scenario is summarised in the graph below for a 200 m long wall. This indicator can be included in a scheme to choose the most sustainable solution (most economically advantageous tender), such as the monetization method used in the Netherlands which is based on multiple key indicators.

In this case study, the conclusion is that the EcoSheetPile™ steel sheet pile wall has the lowest carbon footprint, the difference being 44 % compared to the diaphragm wall. A sensitivity analysis showed that modifying some of the parameters did not impact significantly the above-mentioned number, and in no case reversed the result. Note: the conclusions cannot be simply transposed to other situations, nor to other countries, without applying adequate correction factors.

Note:

The conclusions cannot be simply transposed to other situations, nor to other countries, without applying adequate correction factors.

Introduction

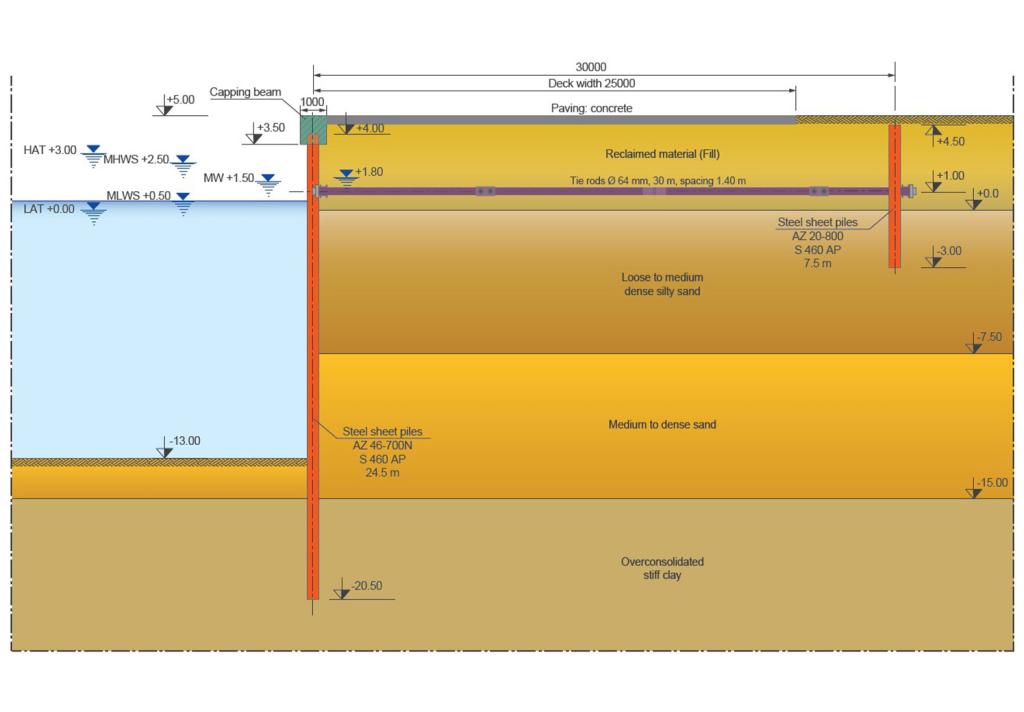

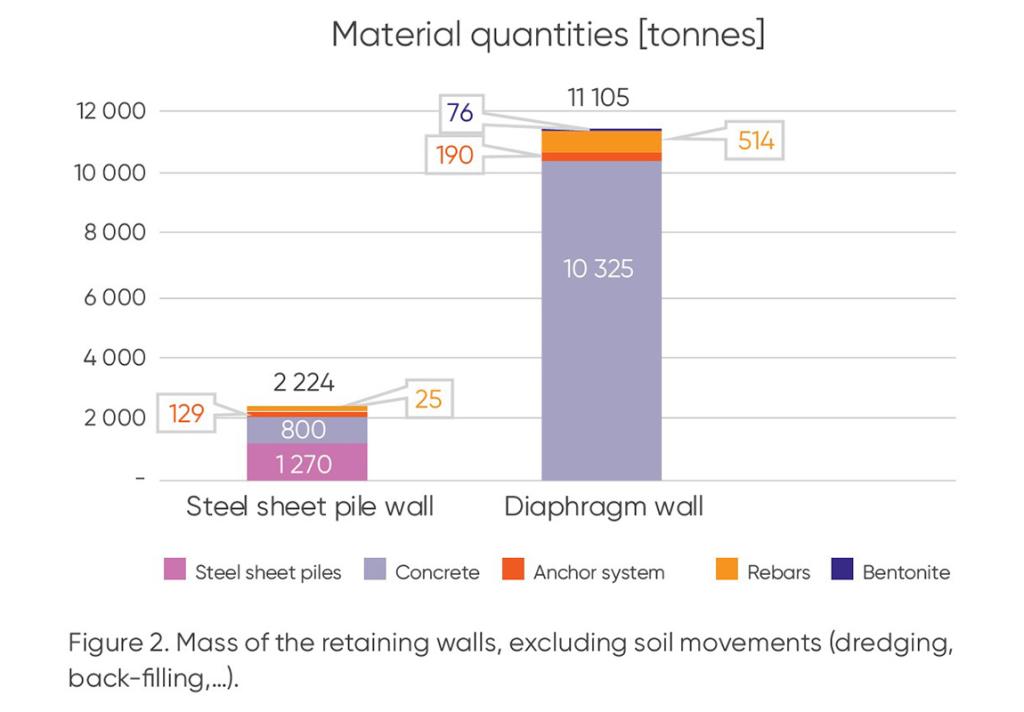

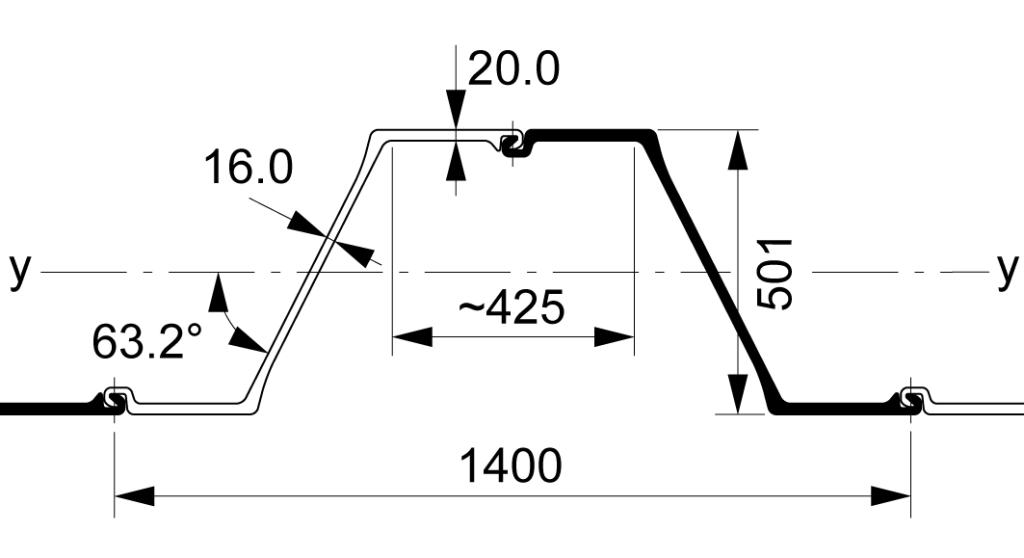

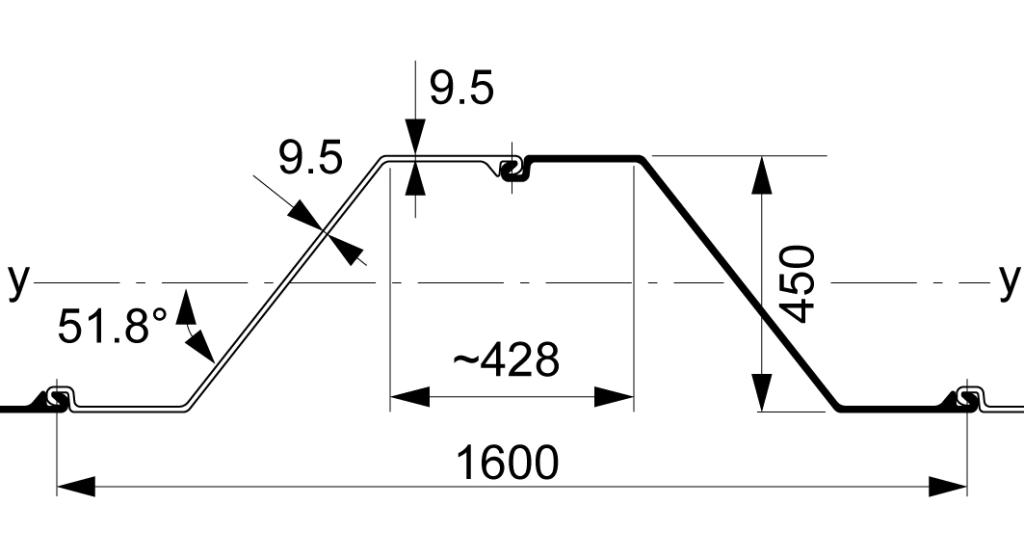

The sheet pile wall is designed with a 24.5 m long standard AZ 46-700N section, in steel grade S 460 AP, and the anchor wall consists of a 7.5 m long AZ 20-800 in S 460 AP. Both walls are connected with 30 m long steel tie-rods of a diameter of 64 mm, spaced at 1.40 m (centreline).

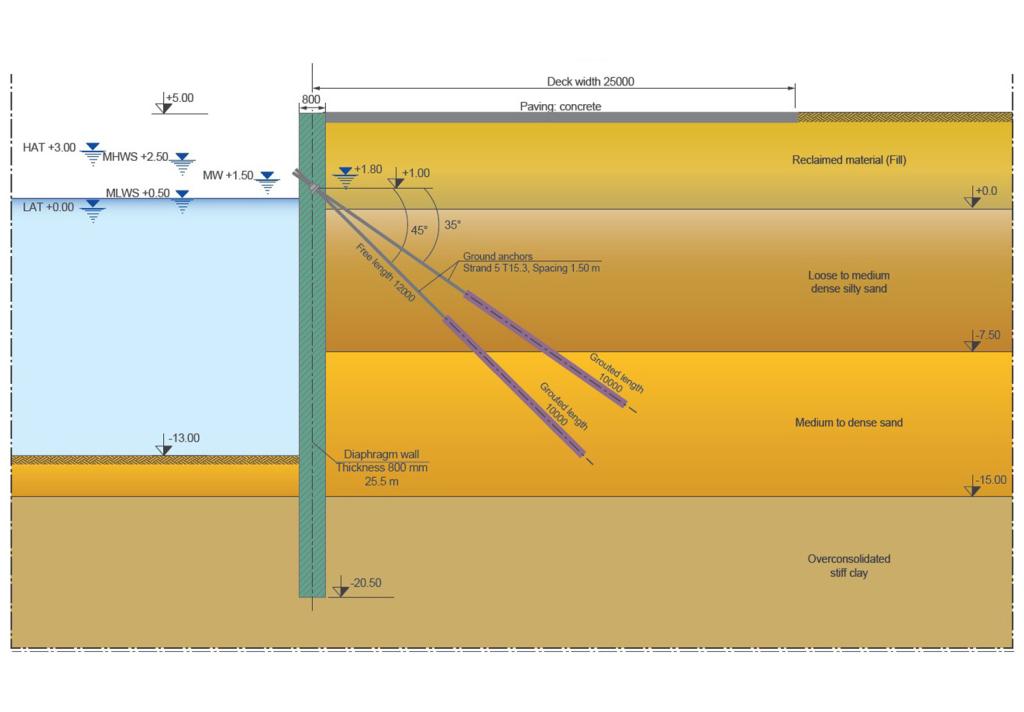

The diaphragm wall is 25.5 m high, with a thickness of 800 mm, and with two 22.0 m long active anchors located at the elevation +1.0 m.

It turned out that under the chosen conditions and assumptions, the SSP wall is around 20% more costeffective than the D-Wall, and that the cost of the deck on pile structure is much higher compared to the two other alternatives. Hence, considering the significant differences, it was decided that the LCA would focus on the two solutions that were economically more attractive: SSP and D-Wall.

Bill of Quantities and Life Cycle Analysis

The Bill of Quantities obtained in this design project serves as the input for the Life Cycle Analysis.

The most sustainable structure can be determined in different ways. The monetization method used in the Netherlands was chosen for this analysis.

There are several key environmental indicators that can be used to compare the most sustainable solutions, such as the MKI in the Dutch method. However, this LCA focuses on the Global Warming Potential (GWP) which is the main factor influencing the rise of the temperature on our planet. Other environmental parameters were analysed and show similar trends as the GWP, with the exception of two parameters.

The LCA was performed by the R&D department of ArcelorMittal in 2020, and peer-reviewed by a panel of three independent experts. The conclusion of the reviewers is that the LCA report has been performed in a professional and unbiased way, and that the conclusions are correct.

The variability of key parameters can influence significantly some results; hence a sensitivity analysis of key parameters was performed, and it confirms that their variation has a limited impact on the results, but never reversed the conclusion from the base scenario.

Goal, scope and assumptions

Methodology

Data

Preference was given to the most relevant and recent sources. The database was built on the following elements:

- Environmental Product Declarations (EPDs), following the standard EN 15804 and registered in IBU. Those data are public and peer reviewed,

- Gabi Database 2018 for transportation as well as construction site and in-use processes.

Representativeness and consistency of the data was checked, and whenever possible, Belgian, German or European EPDs and databases were used. Note that some inherent cut-off might be done in the data, but all the data in the EPDs are compliant with European standards.

The selected steel sheet piles are manufactured in ArcelorMittal’s mill in Belval, Luxembourg. The data for steel sheet piles was extracted from ArcelorMittal’s EcoSheetPiles™ EPD. Note that since this is an LCA being performed for a specific project, the values form the EPD were adapted to fit the project specific assumptions. Therefore, a simple tool was developed by the R&D department.

Rebars could be delivered from any mill in Europe, hence the difficulty in choosing a specific mill. The best option is to consider one EPD and to calculate an average distance from mills covered in the EPD to the job-site. Structural steel such as the waler beams are assumed to be fabricated in one of the mills in Luxembourg (Belval or Differdange). An EPD for steel beams manufactured in Differdange was selected.

Concrete is assumed to be fabricated in a plant close to the port of Antwerp. Specific EPDs for concrete, with and without module D, were used.

Transport

The environmental impact of the transport modes is taken from the Gabi database from 2018. It contains several categories for each transport mode, for instance an “articulated lorry with a maximum payload of 27 tonnes, Euro 0-6 mix”.

The LCA considers the following assumptions for the transport:

- steel sheet piles: 250 km by rail - from the mill in Belval (Luxembourg) to the port of Antwerp in Belgium,

- rebars: 1400 km by rail - average distance from the mills considered in the EPD to Antwerp,

- other steel elements: 250 km by rail – from the mill in Belval or Differdange (LU) to Antwerp,

- concrete: 10 km by truck - from a batch plant close to the port of Antwerp.

End of Life practices

Steel sheet piles and other steel elements from the steel solution are assumed to be recovered after the service life. It is quite rare to reuse sheet piles that have been used in a permanent wall for 50 years, hence two scenarios with 0 % reuse were analysed:

- 95 % recycling and 5 % landfill,

- 99 % recycling and 1 % landfill.

In the EcoSheetPiles EPD, the chosen assumptions are that 25 % are reused, 74 % recycled and 1 % landfilled. The method used to adapt the values from the EPD to above scenarios is explained in detail in the report.

The diaphragm wall could only be partially demolished, so that only a portion could be recovered and recycled / landfilled. This distinction leads also to two different scenarios.

Monetization

Monetization is a commonly and politically approved approach to reflect the economical actors’ position to global warming and ecological issues. This approach is not compliant with ISO 14040-44 but is applied in Belgium and the Netherlands. This methodological process can address the issue of evaluating a fair and appropriate equilibrium between environmental impacts and costs.

For instance, the default value of 1 tonne of CO2-eq. is taken as 50 € in the Netherlands, and within a range in Belgium (up to 100 €). The factor is used to multiply the calculated CO2-eq. content.

In the Netherlands, the method leads to a global index called MKI. It considers several parameters that are not in the standard European EPDs (i.e. toxicological) and weighting factors for each parameter.

Additionally, the method subdivides the data for the LCA in three different categories. The first category corresponds to a specific EPD for a specific product (usually from a single manufacturer), whereas the third corresponds to generic data (average values from available databases or manufacturers) and is penalised by a specific weighting factor to take into account the averaging and spreading of generic data. Consequently, manufacturers that want their products to be part of “Category 1” data must develop a specific EPD for the Netherlands. Note however that this approach has a weakness: in specific cases it might be more favourable to use generic data than a specific EPD which has a very high environmental impact!

Results

Moreover, the contribution of phases A1-A3 to the whole life cycle is more than 70 % in both cases (around 70 % for the sheet pile solution, around 90 % for concrete).

Additional indicators were analysed: Acidification Potential, Abiotic Depletion Potential Elements, etc. Please refer to the report for more details. The trend is similar to the GWP except for Use of Fresh Water and Abiotic Depletion Potential Fossil where the environmental impact is larger for the steel solution.

The comparison of the indicators shows a sufficient difference between the two alternatives to justify the statement that “the environmental impact of steel sheet piles is lower than that of the diaphragm wall”. Indeed, assuming a 5 % uncertainty on each input of the study, a difference of minimum 10 % is essential to demonstrate a clear difference between alternative solutions. This condition is observed for the indicators that were analysed.

Sensitivity analysis

Concrete carbonation at use phase

Carbonation in Module D is taken into account, but it was excluded in Module B1 because the main portion of the concrete is submerged, so that concrete carbonation during the use phase in this particular application is highly improbable. Nevertheless, an evaluation of this parameter was performed.

The conclusion is that applied to the whole concrete volume, the gap between the steel solution reduces from 44 % to 41 %.

Concrete EPD

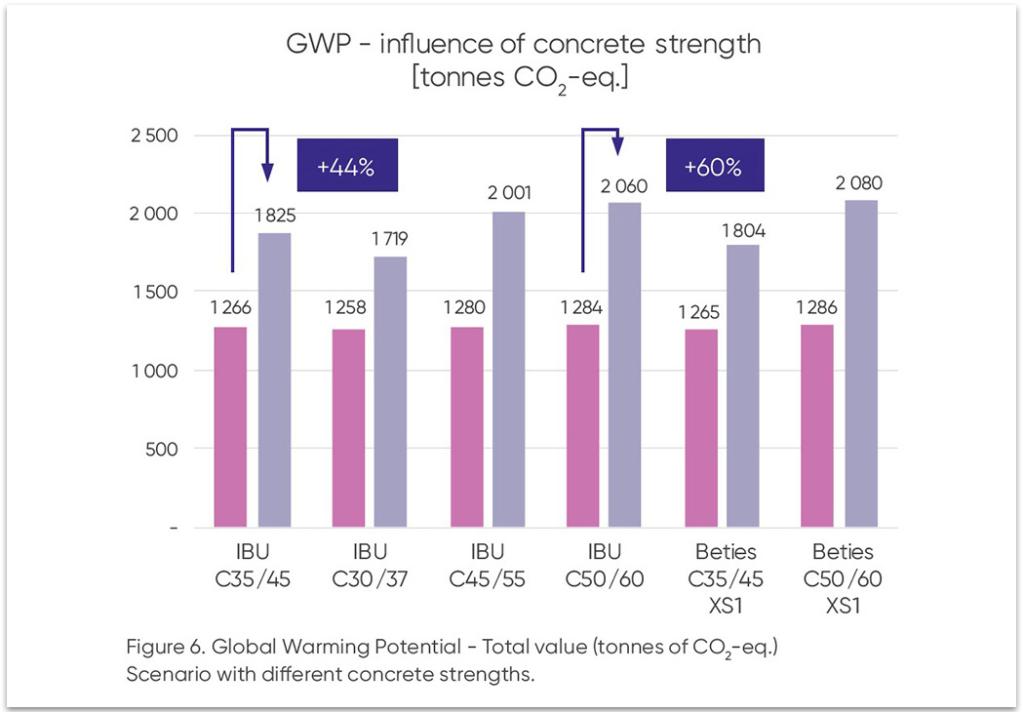

Different EPDs for concrete were considered in this sensitivity assessment, and to confirm that the electricity mix has no or limited influence on the GWP of concrete, a set of EPDs from France and from Germany for different concrete strengths was chosen: C 30/37 up to C 50/60.

Higher strength concrete increases the gap between the steel solution and the concrete solution, lower strength concrete reduces the gap.

Note: a comparison with concrete based on CEM III cement was not analysed due to the current inconsistency of slag allocation between steel and cement industries.

End-of-life scenario

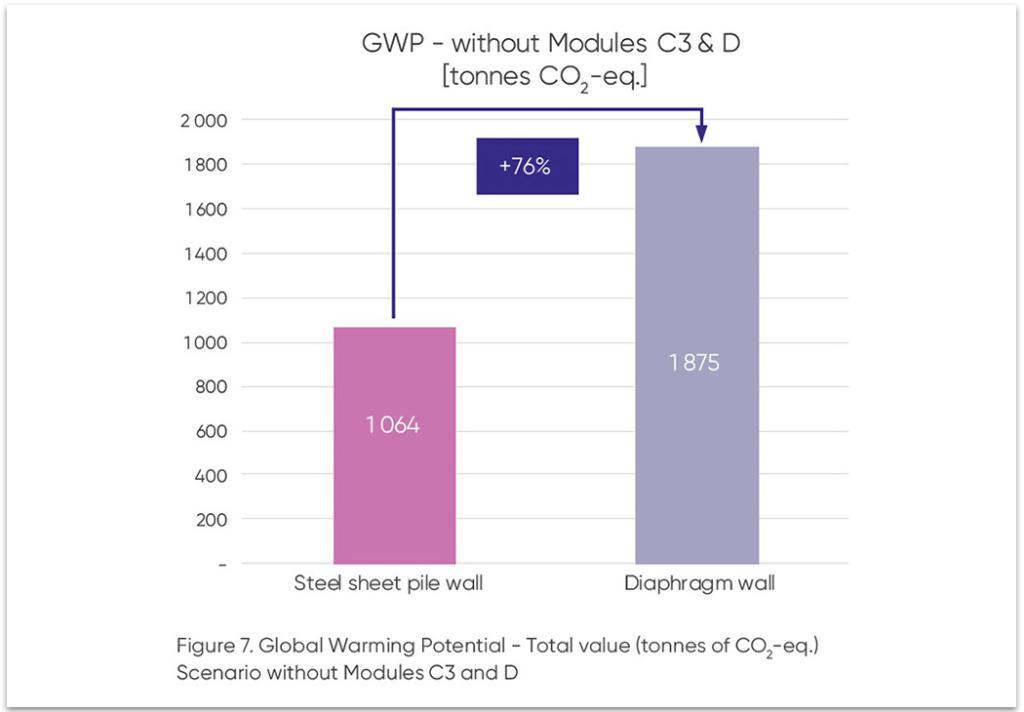

The assessment of the influence of the end-of-life scenario is performed by ignoring the deconstruction / demolishing of the structure for each alternative. Hence the system boundaries are modified by removing phases C3 and D.

Figure 7 shows an increase of the difference between the steel and the concrete solution.

This is mainly due to the fact that for the EcoSheetPiles™ Module D leads to a burden, due to the negative “Net Scrap Value” (more scrap is consumed in the EAF production process than is available for recycling at the end of life), whereas for the concrete it is beneficial through carbonation at the end of life.

Corrosion losses

A precise loss of steel mass due to corrosion is hardly predictable because the corrosion phenomenon differs by exposure zone and by location.

Several effects during the use phase may have a significant influence on this parameter. When more accurate long-term local measurements are not available, it is usual to assume the corrosion rates proposed in Chapter 4 of the standard EN 1993-5.

Based on this standard, the total loss of steel due to corrosion add up to around 136 tonnes. Hence, the reuse and recycling rates were adapted to 0 % reuse, 88.3 % of recycling, and 11.7 % landfill.

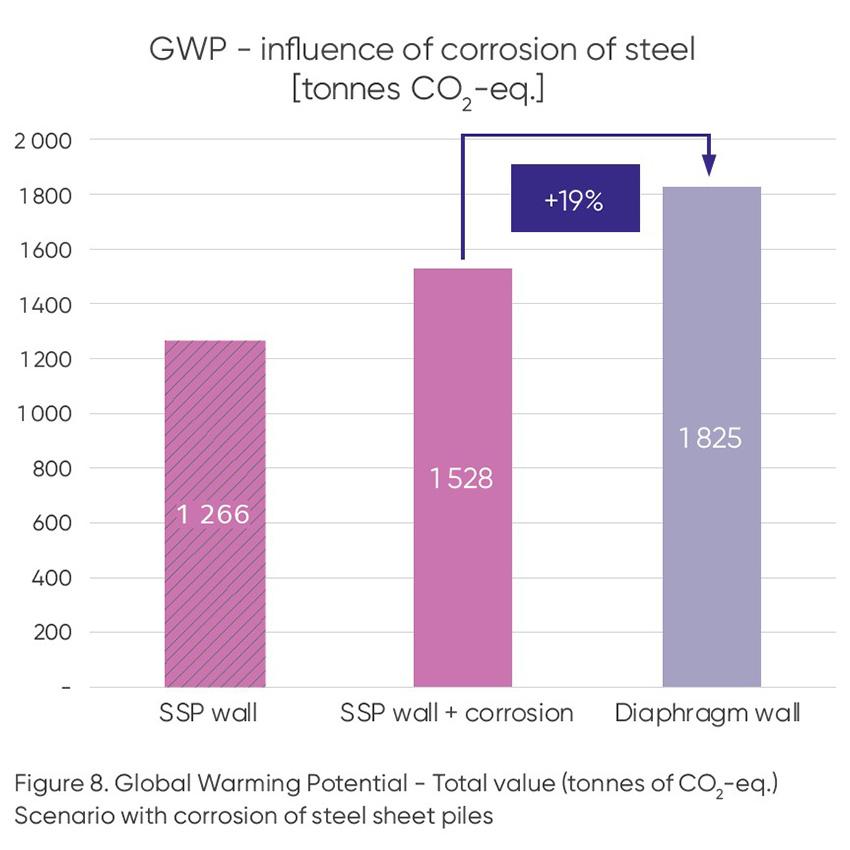

If the concrete structure would not suffer any similar damage (corrosion of the rebars for instance) during the service life, this worst-case scenario for the steel solution leads to a difference in GWP of +19 %, less than the +44 % from the base scenario (see Figure 8).

Conclusion

The sensitivity analysis confirms the results from the base scenario in all the cases: the GWP of the concrete structure (D-Wall) is significantly higher than that of the steel sheet pile solution, varying from +19 % to more than +76 % for the extreme scenarios.

Conclusions, limitations & general comments

General comments

EPDs are currently a tool that in a certain way guarantee a quite fair and transparent assessment of the environmental impact of a specific product or service. As a manufacturer, we believe that if it is used in a correct manner, it is an excellent tool to compare different products and different alternatives. It will incentivise manufacturers to improve their productivity and reduce their environmental impact.

However, we have also noticed that not all EPDs have the same quality and fair assessment, and can sometimes be misleading. EPDs should be worked out by environmental experts that are also specialised in the industry for which the EPD is applicable to prevent wrong assumptions or to miss some key processes.

Generic EPDs are a nice tool to compare different alternatives, like in our example, a steel structure versus a concrete structure, at a feasibility stage or design stage for instance. But when it comes to the comparison of the proposed solution for a tender, a specific EPD from one manufacturer for the proposed product should be required. A product that has a major impact on the LCA result but which is not covered by a specific EPD should be penalised, for instance by using a weighting factor relative to the best-in-class product with a specific EPD.

Disclaimer

The technical and economic analysis of this case study was performed by the Belgian consulting engineers Tractebel for ArcelorMittal in 2018. The design assumptions were determined for a cruise ship terminal in soil conditions that are typical for Belgian ports. From an engineering point of view, such simplified assumptions for a soil can be used for a feasibility study or for a comparison of different alternatives.

ArcelorMittal emphasises on the fact that Tractebel has performed an objective and unbiased case study. The analysis is a purely hypothetical case study with its limitations on reliability on costs and techniques, since these aspects can be very dynamic in markets and different subsoils.

This case study is not a project specific design, therefore neither ArcelorMittal nor Tractebel can be held responsible for choices made in specific projects based on the design or conclusions of the report prepared by Tractebel.

The Life Cycle Assessment (LCA) was performed inhouse by the R&D department in 2020, and peer-reviewed by a panel of three independent experts in 2020. The conclusion of the reviewers is that the LCA report has been performed in a professional and unbiased way, and that the conclusions are correct. Key parameters were submitted to a sensitivity analysis that confirmed the basic scenario; the variation of the parameters did not reverse the results and conclusions of the basic scenario.

The text in this brochure is a summary of these two reports. It was edited in order to focus on the key points of the reports with a minimum of technical explanations. Although the content and conclusions are in line with the original reports, ArcelorMittal’s engineers added some remarks and comments which complement the information contained in the original reports. Some figures, tables and sketches were edited, removed or replaced by new ones prepared by ArcelorMittal. In case of errors in the transcription, only the text and other elements from the original reports are binding.

The technical report from Tractebel and the peer-reviewed LCA report are available on request.

References

- TRACTEBEL ENGINEERING S.A, Methodic Comparison of Retaining wall solutions, 2018.

- ArcelorMittal Global R&D, LCA methodological report - Comparative study of Steel Sheet Pile and Concrete Slurry Wall in quay infrastructure application, Luxembourg, 2020.

- Solinen & al - panel review of 3 experts, Critical review of the LCA - Comparative study of Steel Sheet Pile and Concrete Slurry Wall in quay infrastructure application, 2020.

- Stichting Bouwkwaliteit, Determination Method - Environmental performance - Buildings and civil engineering works, Rijswijk, 2019.

- ISO, ISO 14040:2006-07 - Environmental management - Life cycle assessment - Principles and framework, 2006.

- ISO, ISO 14044:2006+A1:2018 - Environmental management - Life cycle assessment - Requirements and guidelines, 2018.

- CEN, EN 15978:2011. Sustainability of construction works.

- Assessment of environmental performance of buildings. Calculation method, Brussels, 2012.

- CEN, EN 1997-1:2004+A1:2013. Eurocode 7. Geotechnical design. General rules, Brussels, 2013.

- CEN, EN 1993-5:2007. Eurocode 3. Design of steel structures. Part 5: Piling., Brussels, 2007.

- CEN, EN 1992-1 (series). Eurocode 2. Design of concrete structures, Brussels, 2004-2019.

- CEN, EN 15804:2012+A1:2013. Sustainability of construction works. Environmental product declarations.

- Core rules for the product category of construction products, Brussels, 2013.

- IBU - Institut Bauen und Umwelt e.V., PCR for Building-Related Products and Services. Part A - Calculation rules for the Life - Cycle Assessment and Requirements on the Project Report - v 1.7, Berlin, 2018.

- Thinkstep (Sphera), Gabi database, Berlin, 2018.

- IBU - Institut Bauen und Umwelt e.V., EPD “EcoSheetPiles™” - EPD-ARM-20180069-IBD1-EN, Berlin, 2018.

- EFFC - DFI, EFFC DFI Carbon Calculator Methodological & User Guide v2.1, 2013.

Ports have been faced with quite many challenges in recent years. On the one hand, the sea traffic has steadily increased, modern vessels are getting bigger; on the other hand, our planet is struggling with the greenhouse gas emissions.

Ports need to expand, to build new berths, but how to achieve these goals without harming the environment?